About Us

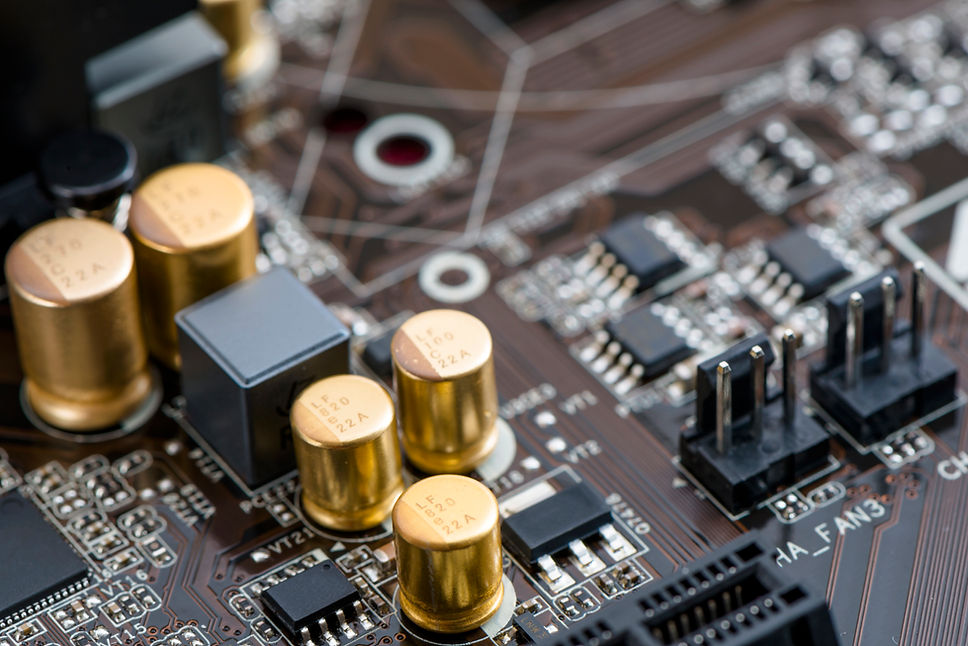

We are a dynamic electronics manufacture company specializing in end-to-end electronic product development and PCB assembly services. With over a decade of expertise in electronics R&D, the company has been at the forefront of innovative projects, including satellite payload development (Azaadisat 1, Azaadisat 2, SDSat), high-altitude balloon (HAB) missions, and advanced VR simulator systems. Led by a highly experienced team, Takvar offers a full spectrum of services from concept to PCB realization—covering SMT/THT assembly, embedded design, and prototype development—empowering clients to bring cutting-edge electronic solutions to life.

Services

At Takvar Technologies, we offer end-to-end electronics manufacturing and development services, including PCB Assembly using both Surface Mount Technology (SMT) and Through-Hole Technology (THT) for precise and reliable circuit board production. Our expertise in PCB Rework allows us to efficiently repair and modify existing boards, extending product life and reducing costs. We also specialize in Electronics Product Development, turning ideas into fully functional prototypes and production-ready devices. Additionally, our Wire Harness Assembly services deliver high-quality, custom wiring solutions that ensure safe and organized electrical connectivity across various industries.

Why Choose us?

Experienced Team

Skilled technicians with years of industry experience

Quality Assurance

Strict quality control at every stage

Customer Focus

Tailored solutions to meet your specific needs

Flexible Production

From prototypes to

large-scale manufacturing

.jpeg)

.jpeg)

.jpeg)